Bradford research powers first global launch of plastic‑free drink technology

A breakthrough University of Bradford technology that could eliminate billions of single‑use plastic bottles is hitting the global market this week, with a New Zealand drinks launch built on the University’s patented co‑crystal science and manufactured under exclusive licence by Yorkshire firms Octopoda Innovations and Health Innovations (UK).

A University of Bradford research breakthrough with the potential to remove billions of single‑use plastic bottles from global supply chains has entered the international market for the first time.

The breakthrough follows the commercial launch of a new plastic‑free effervescent drinks format based on patented Bradford‑developed co‑crystal stabilisation technology.

Professor Anant Paradkar, who designed the method, described it as “a breakthrough moment for Bradford research.”

Changing the world

He said: “I am proud that technology developed by this university – and which has the potential to remove billions of plastic bottles from the supply chain – is now on the shelves.

“Our partner and licence holder Octopoda Innovations Ltd and Health Innovations (UK) Ltd have invested siginificantly in the development of the technology over the last eight years to take the patent concept from laboratory scale to commercial production and we take pride in the fact these products are manufactured in West & North Yorkshire.”

“This is a real breakthrough moment for this technology, which has the potential not only to save manufacturers millions in costs but to make a measurable impact on reducing plastic waste. This is a prime example of how our research and innovation really is world leading and world changing.”

The product, launched this week across New Zealand and Australia, is being described by independent media as the world’s first fully plastic‑free drink tablet, enabled by a stabilisation method that allows effervescent products to be stored in 100% compostable packaging rather than plastic or metal.

Co-crystal design

At the heart of the innovation is a co‑crystal design created and patented by researchers at the University of Bradford, developed and manufactured by Octopoda Innovations Ltd and Health Innovations (UK) Ltd under its exclusive licence and in West & North Yorkshire.

Professor Sherrif El-Khamisy, Pro-Vice-Chancellor for Research and Innovation, said: “This is exactly the kind of research and innovation that defines the University of Bradford. We are committed to creating technologies that don’t just advance knowledge but deliver real‑world impact at global scale. Seeing this platform enter the international market for the first time demonstrates how our research translates into sustainable solutions that genuinely change lives.”

Until now, global manufacturers had been unable to stabilise effervescent tablets without resorting to sealed plastic containers, a technical barrier that major pharmaceutical and fast-moving consumer goods companies have spent decades attempting to overcome.

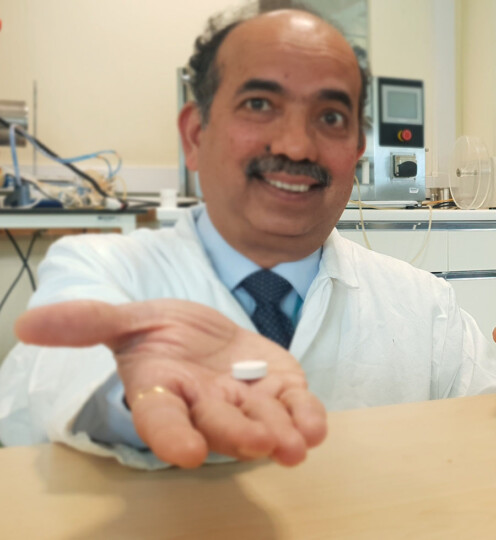

Professor Anant Paradkar, from the University of Bradford, who designed the co-crystal technology used to remove liquids from the supply chain. Picture credit: University of Bradford.

Consumer habits

The product’s arrival on the market comes at a critical time. The global soft drinks industry produces an estimated 583 billion single‑use plastic bottles a year, with less than 10% effectively recycled. Independent reporting also highlights that companies worldwide have the capacity to produce 20,000 PET bottles every second, and that drinks containers account for 45% of litter on typical urban streets.

By enabling beverages to be transported and sold in solid tablet form, the Bradford‑born technology eliminates the need to ship liquids – a shift that could dramatically reduce carbon emissions, material use and transportation costs across global supply chains.

Professor Paradkar added: “There is no longer any need to transport billions of tonnes of liquids for a range of cleaning, health and lifestyle products. The technology now exists to deliver these in tablet form and store them in biodegradable cardboard packets. The thing we need to change now is consumer habits.”

He added he expected further commercial applications of the platform in the months ahead as interest and awareness continues to grow.